Spices refer to natural plant-based materials used to flavor and enhance the taste of food, imparting aromas ranging from fragrant to pungent and spicy. Spices are rich in volatile essential oils, making it crucial for the industry to focus on improving yield and controlling the loss of active components during the spice powder production process.

1. Traditional Spice Powder Production: Advantages and Drawbacks

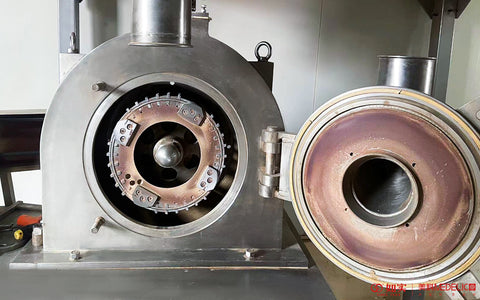

Traditional spice grinding machines mainly include turbine-style grinders, hammer mills, and claw-type grinders. These processes involve utilizing ultra-high linear speeds to repeatedly collide and frictionally grind the spice materials, achieving the purpose of powdering spices.

The advantages of traditional spice powder production lie in its simplicity of technology and equipment, as well as low investment costs. However, its drawbacks are apparent, primarily concerning food safety risks, loss of active components, and low yield.

2. Reasons for Low Yield and Loss of Active Components in Spice Powder Production

The ultra-high linear speeds in spice grinding machines generate significant airflow within the chamber. While this airflow aids in better material expulsion and flow, it also accelerates the loss of active components and the generation of dust, leading to aroma loss and directly impacting yield.

Repeated collisions and friction between spice materials result in high temperatures, easily surpassing 70°C, thereby accelerating the decay and volatilization of active components.

The loss of active components leads to a decline in spice powder quality, while the generated dust affects the production workshop environment. Aroma leakage affects the surrounding environment, necessitating the addition of dust removal and deodorizing equipment, further decreasing yield and increasing costs.

3. The Road to Spice Powder Production with M-Lite Technology

By addressing the pain points in the spice industry, M-Lite has independently developed four major grinding technologies and a closed-loop circulation device, tailoring corresponding grinding processes based on the characteristics of different spices and their applications.

Technology 1: Low-speed constant temperature grinding, wall-breaking grinding, maintaining intact active ingredients and flavors.

Technology 2: Temperature-controlled grinding, full-process closed-loop production, effective substance supplementation and recovery, preserving complete flavor and texture.

Technology 3: Low-speed ambient temperature shearing, uniform particle size, no separation of husk and flesh, retaining original flavor and texture.

Technology 4: Ambient temperature closed grinding, uniform particles without powder, maintaining unchanged active ingredients and flavors.

By employing these technologies and the closed-loop circulation device, M-Lite tackles the grinding challenge, keeping grinding temperatures between ambient and 40°C, with no airflow or dust generation inside the grinding chamber. There's no need for additional dust removal or deodorizing equipment. Loss of active ingredients is minimized, yielding improvement, ultimately leading to enhanced powder quality and reduced costs.